Fabrication companies rely on several techniques to make the products that customers order. For instance, they do welding, laser cutting, and prototyping, among other things. However, one thing that different industries request the most is CNC router cutting services.

CNC Versus Conventional Machining

Machining services fall into two categories - CNC machining and conventional machining.

Custom CNC Cutting in Toronto

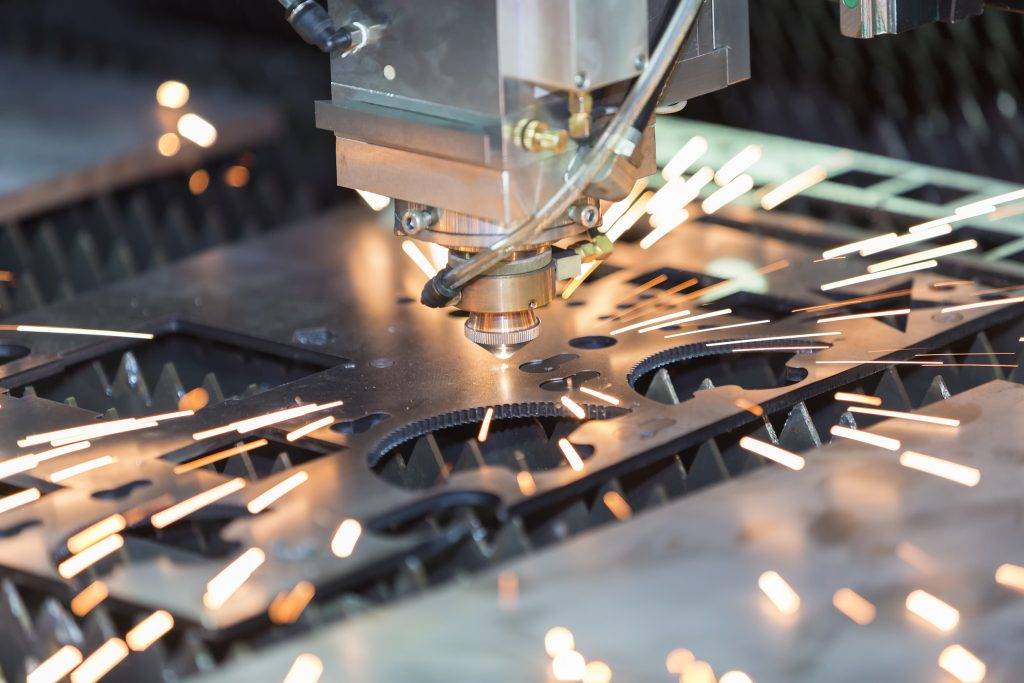

CNC, which stands for Computer Numerical Control, involves machining that operates via a software program. For this, information gets entered into the system, which starts the machining process using preprogrammed computer destinations. Those destinations guide the machine tools throughout the cutting process. With CNC router cutting services, the machining tools never come into contact with the raw material workpiece.

Conventional Router Cutting Services

The way the conventional process works is quite different from a CNC industrial router. In this case, a trained operator must handle machining tools directly. They’re responsible for controlling the way each performs, whether drilling, milling, cutting, and so on.

Key Benefits of a CNC Industrial Router

Of the two methods, custom CNC cutting services are far more advantageous. Below are several examples of why this is the technique that a lot of industries and fabrication companies prefer.

Few Skills Required

Remember, a CNC industrial router operates via a preprogrammed computer. So, an individual doesn’t need specialized skills to enter the project specifications into the software. This person can set the machine up quickly and easily, even without a lot of experience. For that reason, some industries purchase machines for CNC fabrication to perform the work in-house. However, many companies still rely on a fabricator for CNC router cutting services because they’re convenient and time-saving.

Repeatable Products

Another thing that makes custom CNC cutting in Toronto stand apart from conventional machining is repeatability. In other words, the computer program can create thousands of the same parts or components, each with extreme precision. With the other method, a fabricator would need to make the product many times over.

Enhanced Production Options

A CNC industrial router also expands production options. Because the software used for CNC machining is technically advanced, it can create things that a human would struggle to complete. As a result, a fabrication company can offer its customers more creative and versatile solutions.

A Trusted Source for Custom CNC Cutting in Toronto

If you need this type of fabrication service, contact us at Weldflow Metal Products. Along with the benefits mentioned, CNC machining is a great way to run a seamless operation with fewer workers. That, combined with the speed at which CNC machining works, reduces costs.